Capillaries & Thermowells

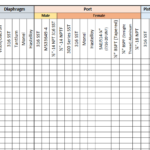

Capillaries — Optional Tube Lengths

Standard series temperature switches are furnished with a 5’ capillary. Optional 10’, 15’, and 25’ capillaries are available. Order as listed below:

- 10’ capillary (3.05 meter): When ordering add –7001 to model number

- 15’ capillary (4.57 meter): When ordering add –7002 to model number

- 25’ capillary (7.62 meter): When ordering add –7003 to model number

How to order:

1. Specify standard model number of temperature switch desired.

2. Add the above number that specifies capillary length to end of standard number.

EXAMPLE: To order 646TUE1 with 15’ capillary, specify 646TUE1–7002

Thermowells

Readily available convenience items for use with temperature switch models.

How to order:

Specify thermowell part number as a separate line item.

4 ½” (114.3 mm), 7 ½” (190.5 mm), 10 ½” (266.7 mm), 13 ½” (342.9 mm)

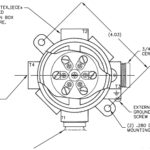

Junction Boxes

Junction Box Options:

- 141-18 (Outlet: 3/4”-14 NPT Aluminum)

- 141-19 (M20 Aluminum)

* For 6905 Series Use PN: 141-25 - 141-20 (3/4” NPT Stainless Steel) – Model shown above

* For 6905 Series Use PN: 141-26 - 141-27(M20 x 1.5P ElectricalConduit and M20 x 1.5P Outlet Stainless Steel)

- 141-28(1/2″-14 NPTElectricalConduit and M20 x 1.5P Outlet Stainless Steel)

Junction Box Standard Features:

- Explosion proof

- Weatherproof

- Suitable for hazardous areas

– Div 1, Div 2, Zone 1, Zone 2, IP 68 - Certified to ATEX, CSA, FM, IECEx

Obsolete Models:

- 141-21 (Use part number 141-18)

- 141-22 (Use part number 141-19)

Standard Features:

- Weatherproof

- Suitable for non-hazardous areas

How to Order

CCS Junction Boxes can be purchased as a separate line item to be installed in the field or they can be purchased attached to a CCS switch.

- To order the junction box as a separate line item (unattached), please place an order for one of the five models listed above.

- To place an order for a switch attached to a junction box follow the example below:

- Example: 6900GZE12 with 141-20 Junction Box installed/attached:

Line 1: Switch part number (6900GZE12)

Line 2: Junction box model (141-20) – Note: Attach to switch in line 1.

- Example: 6900GZE12 with 141-20 Junction Box installed/attached:

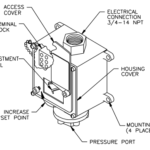

Mounting Kits & Manifolds

Models:

- 89-130 (675 Series Mounting Bracket Kit)

- 89-133 (1/4” 18 NPT 316 Stainless Steel)

- 89-133-1 (1/2” 14 NPT 316 Stainless Steel)

- 89-134-1H (Pipe Mount – Horizontal)

- 89-134-1V (Pipe Mount – Vertical)

Features and Benefits:

- Facilitates dual set points.

- Allows for

- Pressure indication

- Process monitoring

- Functional testing

- Switch calibration

Din Connector Accessories

The new 675 non-hazardous series comes furnishedwith a four blade electrical connector which conforms to DIN-43650. To purchase a standard 611 and 6900 SPDT non-hazardous model including the same electrical connector, pleaseadd the-7075 or -7077 (DIN – gold contacts) modified standard suffix to the end of the part number.

The following DIN accessories can also be ordered as separate convenience items.

Models:

- 69-102: Mating Connector (18 AWG Wire)

- 57-159: Sealing Gasket

Misc Items

Cable Glands, Pipe Mount, Oxygen Cleaning and Epoxy Paint offered.

Tagging:

Tagging requirement must be specified on the face of the purchase order. Indicate whether mylar or stainless steel tagging is required.

Factory Settings:

Factory setting of field adjustable models offered. Please specify required set point on the face of the purchase order.

Certifications

Contact us to request a complete certification documentation packageor certification history. Current certification“supplements” available for download below. Note: Some series have multiple certifications from a single agency.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

CONFLICT MINERALS FREE

Conflict Minerals (Dodd-Frank Wall Street Reform and Consumer Protection Act, Section 1502) Declaration of Conformity

On August 22, 2012, the U.S. Securities and Exchange Commission (“SEC”) adapted final rules to implement reporting and disclosure requirements related to “Conflict Minerals”, as directed by the Dodd-Frank Wall Street Reform and Consumer Protection Act of 2010. These rules require manufacturers who file certain reports with the SEC to disclose whether the products they manufacture or contract to manufacture contain “Conflict Minerals necessary to the functionality or production” of those products that directly, or indirectly, finance or benefit armed groups in the Democratic Republic of the Congo or an adjoining country. The term “Conflict Minerals” is defined as tantalum, tin, tungsten, gold and their derivatives.

Custom Control Sensors, CCS, as a privately held corporation, is not subject to the Conflict Minerals reporting requirements directly; however, as a supplier to publicly traded companies, we are committed to helping our customers comply with their reporting requirements on this issue and as a concerned global citizen, we believe it is the right thing to do. In this regard, we have conducted a “Reasonable Country of Origin” inquiry process, as necessary, with our relevant suppliers. Based upon the information obtained in that inquiry process and, to the best of our knowledge and belief, the products that we have supply to you do not contain Conflict Minerals.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

ISO/AS

ISO 9001:2008 / AS9100:2009

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

List of Models Certified to ATEX, GOST and IECEx

Download .pdf

ATEX

6900*E, 674DE, 611*E Series

Sira 08ATEX1046X– Download .pdf

642 Series

Baseefa07ATEX0108X – Download.pdf

Baseefa07ATEX0108X/1 –Download.pdf

646 Series

Baseefa 05ATEX0011X – Download.pdf

Baseefa 05ATEX0011X/1 – Download.pdf

Baseefa 05ATEX0011X/2 – Download.pdf

Baseefa 05ATEX0011X/3 –Download.pdf

672DE Series

Baseefa 04ATEX0114X – Download .pdf

Baseefa 04ATEX0114X/1 – Download .pdf

Baseefa 04ATEX0114X/2–Download .pdf

675 Series

Baseefa 08ATEX0347X – Download .pdf

Baseefa 08ATEX0347X/1 –Download .pdf

6403 Series

Baseefa 04ATEX0113 – Download .pdf

6905 Series

Baseefa 03ATEX0700X – Download .pdf

Baseefa 03ATEX0700X/1 – Download .pdf

Baseefa 03ATEX0700X/2 – Download .pdf

Baseefa 03ATEX0700X/3 – Download .pdf

Baseefa 03ATEX0700X/4 –Download .pdf

Baseefa 03ATEX0700X/PT/08/12 – Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

CCOE / PESO

Petroleum and Explosives Safety Organisation (PESO)

6900*E, 674DE, 611*E, 642Y, 672DE**, 675Y, 6905** Series

Download .pdf

646Y Series

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

CE

CE Declaration of Conformity

Download .pdf

CE EMC Directive

Download .pdf

CE Low Voltage Directive (LVD)

Download .pdf

CE Pressure equipment Directive (PED)

Download.pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Country of Origin – U.S.A.

Certificate of Conformance – Domestic Origin

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

CRN

CRN Certificate – Alberta

Download .pdf

CRN Certificate – British Columbia

Download .pdf

CRN Certificate – Manitoba

Download .pdf

CRN Certificate – Northwest Territories

Download .pdf

CRN Certificate – Saskatchewan

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

CSA

CSA Certification for 604 Series

Download .pdf

CSA Certification for Hazardous Areas

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Dual Seal

Contact Factory for Certificate

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

GOST

GOST-K Certification

Download .pdf

GOST-K Permission for Use

Download .pdf

GOST-R Certification

Download .pdf

GOST-R RTN Permit

Download .pdf

GOST-U Certificate for 646 and 673 Series

Download .pdf

GOST-U Certificate for 6905 Series

Download .pdf

GOST-U Permission for Use

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

IECEx

6900*E, 674DE, 611*E Series

IECEx SIR 10.0193X –Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

NACE

NACE Certification of Compliance

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

NEMA

NEMA 4XCertification of Compliance

605 Series

Download .pdf

646 Series

Download .pdf

6900 and 6905 Series

Download .pdf

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

RoHS

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

SIL Declaration

Contact Factory – Available upon request.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

UL

UL Certification for Hazardous Areas

Download .pdf

UL for Turck®

Download .pdf

Junction Boxes:

141-18

141-19

141-20

141-23

141-25

141-26

141-27

141-28

Download .pdf

Installation Instructions

10-1091.pdf

604G*, D*, P* Pressure Switch Series

10-1224.pdf

604DZ** -7011 Differential Pressure Switch Series (Russian Version)

10-1094.pdf

604T* Temperature Switch Series

10-1202.pdf

605G*, 605D*, 605P* & 605V*Pressure Switch Series

10-1116.pdf

611* Pressure Switch Series

10-1176.pdf

611GEY* & 611VEY*Pressure Switch Series

10-1124.pdf

642DE* Differential Switch Series

10-1163.pdf

642GE*Y*, 642DE*Y*, 642VE*Y*

10-1126.pdf

645DB* Differential Pressure Switch Series

10-1093.pdf

646* Pressure Switch Series (English & SpanishVersion)

10-1115.pdf

646T* Temperature Switch Series

10-1153.pdf

646GE*Y*, 646DE*Y*, 646VE*Y*

10-1157.pdf

646GE*Y*, 646DE*Y*, 646VE*Y* (SpanishVersion)

10-1181.pdf

646GE*Y*, 646DE*Y*, 646VE*Y* (Russian Version)

10-1154.pdf

646TE*Y* Switch Model

10-1150.pdf

672DE* Switch Model

10-1165.pdf

675GE*, 675DE*, 675VE*, 675GE800* & 675DE800*Pressure Switch Series

10-1168.pdf

675GEY*, 675DEY* & 675VEY*Pressure Switch Series

10-1180.pdf

675GEY*, 675DEY* & 675VEY*Pressure Switch Series(Russian Version)

10-1155.pdf

6403GE* & 6403DE* Pressure Switch Series

10-1159.pdf

6403TE* & 6403TUE* Temperature Switch Series

10-1089.pdf

673DE* Differential Pressure Switch Series

10-1090.pdf

674D* Differential Pressure Switch Series

10-1170.pdf

674DEY* Differential Pressure Switch Series

10-1206.pdf

690P* & 690PE*Pressure Switch Series

10-1211.pdf

6900G* & 6900P* Pressure Switch Series

10-1196.pdf

6900G*-7075/7077 & 6900P*-7075/7077Pressure Switch Series (SpanishVersion)

10-1106.pdf

6900GE* & 6900PE* Pressure Switch Series

10-1166.pdf

6900GEY* & 6900PEY*Pressure Switch Series

10-1213.pdf

6900GEY* & 6900PEY* Pressure Switch Series (Spanish Version)

10-1200.pdf

6900GEY*-7089 & 6900PEY*-7089Pressure Switch Series

10-1193.pdf

6900DEY*Pressure Switch Series

10-1218.pdf

6900DZE* Pressure Switch Series (Spanish Version)

10-1107.pdf

6900T* Temperature Switch Series

10-1186.pdf

6900TEY* & 6900TUEY*Temperature Switch Series

10-1214.pdf

6900TEY* & 6900TUEY*Temperature Switch Series (Spanish Version)

10-1095.pdf

6905G*, 6905D*, 6905P*Pressure Switch Series

10-1217.pdf

6905G* & 6905P* Pressure Switch Series (Spanish Version)

10-1209.pdf

6905GE*-7079 & 6905PE*-7079Pressure Switch Series

10-1208.pdf

6905DZE* Pressure Switch Series

10-1216.pdf

6905DZE* Pressure Switch Series (Spanish Version)

10-1096.pdf

6905TE*, 6905TUE* Temperature Switch Series

10-1178.pdf

6905* Pressure Switch Series (Russian Version)

10-1177.pdf

6905TE* Pressure Switch Series (Russian Version)

Acessories

10-1183.pdf

141-18, 141-19, 141-20Junction Boxes

10-1187.pdf

141-21, 141-22 Junction Boxes

10-1184.pdf

89-130Mounting Bracket

CAUTIONS:

FOR INSTALLATION AND USE OF CCS PRESSURE, TEMPERATURE & FLOW SENSORS:

WARNING:If this switch is used to protect equipment or personnel from unsafe pressure or to guard against the hazardous release of contained substances, it must be installed and operated in accordance with applicable codes, regulations and standards. This switch must be used in conjunction with system design’s (or procedure’s) necessary to mitigate any hazard resulting from its failure. Conform to installation instructions accompanying this switch. Individuals who ignore this warning may suffer serious or fatal injury and do so at their own risk. Custom Control Sensors is not liable for any misuse, abuse, suitability or adequacy of user’s application of the switch. Service by qualified personnel only.

MEDIA:System media must be compatible with the specified wetted materials. Oxygen media cannot be utilized without special cleaning and packaging provided by the factory.

OPERATING CONDITIONS:The electrical load, ambient temperature ranges, and proof pressure specified must not be exceeded. Surge pressurization should not exceed 200,000 psi per second to diaphragm switch models and 1 million psi per second to piston switch models. In installations that will be subject to severe shock, vibration, or other hostile environment conditions, contact the factory to determine suitability.

Field adjustable units should be set no closer than 1/2 turn from either end of their adjustment range.

UL/CSA/BASEEFA/SIRA/ATEX/IECEx:Field repairs or modifications of “certified” and “listed” units may void the listing of the repaired or modified unit. Effective August 2, 2005, CCS implemented Return Switch Authorization Policy. This policy will require that all products returned to CCS be identified with an RMA number assigned by CCS.